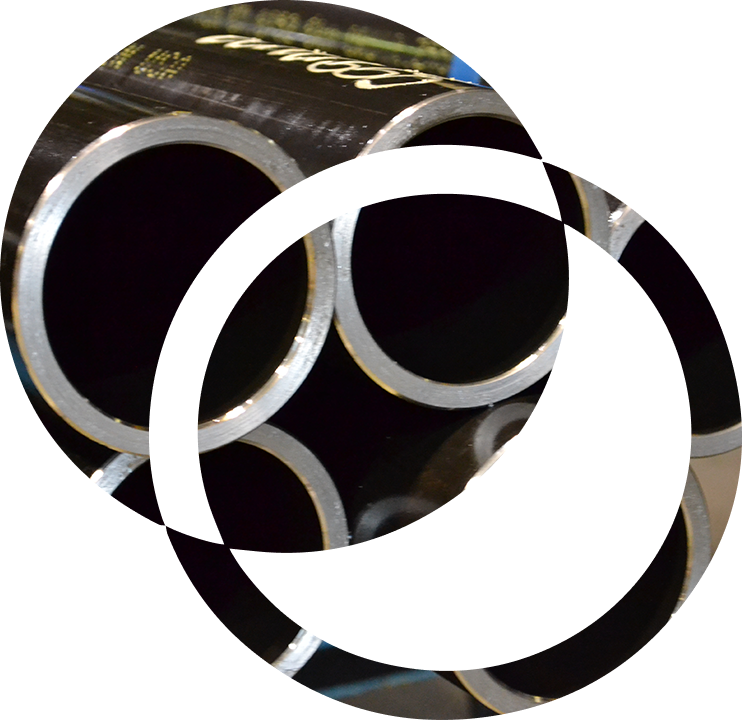

Drawn Over Mandrel

(DOM) Products

PTC manufactures premium DOM tubing products in a wide array of sizes and grades for agriculture, automotive, appliance, construction, recreation, and heavy truck manufacturing.

DOM mechanical steel tubing is manufactured from electrical resistance welded hollow tubing — further processed by cold drawing through dies and over mandrels — resulting in improved surface finishes, mechanical properties and dimensional accuracy. These characteristics, combined with reliable weld integrity, maximum concentricity, and minimal wall variation, create a high-quality, cost-effective choice for demanding applications and machined parts.

PTC has a unique capability with 14 weld mills and 25 draw benches in 6 locations.

PTC’s two hot stretch reducing mills (HSRM) also gives us a unique capability of producing D/t ratios that cannot be produced on an ERW mill. This enables PTC to supply a wide variety of diameter and wall thicknesses.

Special smooth I.D. surfaces are available for critical applications such as hydraulic cylinders and shock absorbers.

These products are typically produced to the requirements of ASTM A513 Type 5 (or Type 6 for SSID) or European standard EN 10305-2.

Common Applications Include:

- Axles

- Bushings

- Fluid power applications

- Gas Springs

- Hydraulic cylinders

- Motor housings

- Shock Absorbers

- Suspension components

- Transmission shafts

PTC Manufactures DOM to the following specs:

Specifications: ASTM A513 T5 & 6, DIN 10305-2, JIS G3444 and G3445 -E-C

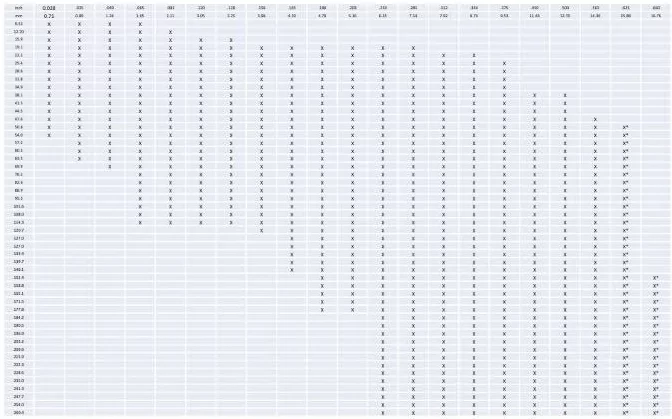

Size ranges

Other sizes outside this range may be within our capability, please inquire to:

Round and shaped tubing available.

Standard Grades

PTC's DOM Capabilities

Related Products & Services

Cold Drawn Seamless (CDS)

PTC's Cold Drawn Seamless (CDSM) tubing delivers high strength, precision, and machinability, perfect for hydraulic cylinders and heavy equipment.

Learn more

Finishing & Fabrication Services

PTC offers extensive value-added services from cutting and welding to forming, plus inventory management for consistent product flow and quality.

Learn more