A53B Standard Pipe

PTC's Hot Stretch Reducing process enhances the performance of ERW welded pipe by precisely controlling size and properties. Our pipe is proudly Melted and Manufactured in the USA.

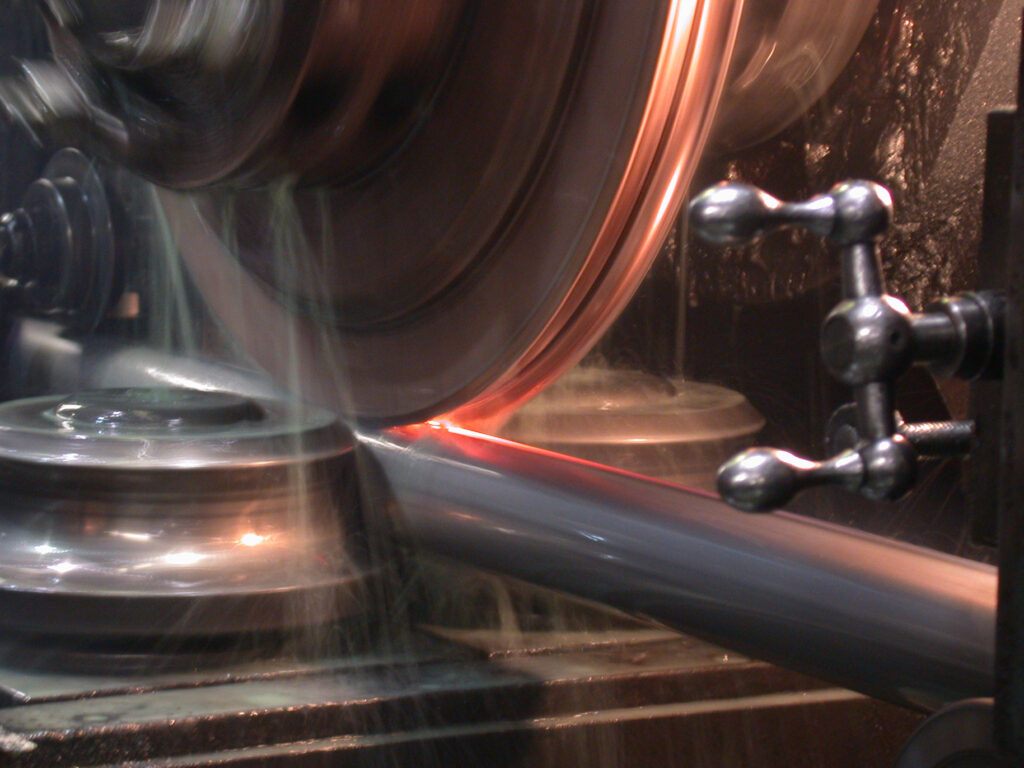

Hot Stretch Reducing is an additional hot finish process for ERW products. This process involves taking an ERW pipe, with completely removed weld flash, and heating and passing the product through a series of rollers that reduce the size of the tube in one relatively fast hot working operation.

This operation allows for excellent control of size and properties through enhanced thermo-mechanical processing. The slow cooling of pipe ensures a uniform grain structure that eliminates hot spots to enhances structural integrity.

Advantageous for customers, and suitable for high-performance industrial environments.

While a typical ERW mill produces only limited ranges in size, PTC can further reduce products, while preserving the ductility and elasticity. This process is ideal for improving toughness, reducing brittleness, and providing superior machinability & threadibility to pipe. Uniform performance across all batches ensures dependable results.

Our Darlington plant has inline capabilities to hydrotest, UV coat and stencil of our A53B pipe, using same equipment as our A106 pressure pipe to ensure consistent quality and performance. Additionally, we offer Pickles and Oiled (P&O) pipe options.

Common Applications:

- Feedwater lines

- Steam lines

- Gas lines

- Air lines

PTC Manufactures A53B Standard Pipe to the following specs:

Specifications: ASTM A53/A53M

Related Products & Services

Chrome-Plated Products

PTC's chrome-plated products and machined components offer durability, precision, and superior corrosion resistance.

Learn more

Electrical Resistance Welded Tubing (ERW)

PTC offers premium ERW tubing for diverse needs in agriculture, auto, construction, and more: versatile, cost-effective, with a wide size and grade range.

Learn more

Finishing & Fabrication Services

PTC offers extensive value-added services from cutting and welding to forming, plus inventory management for consistent product flow and quality.